As the meticulous works by Gunner, GR8000 Series adequately embodies the high performance cutting plotter in every aspects, such as superior stability, high precision, high cutting/ plotting speed, extra long distance linear tracking ability, big cutting force, super simple operation, just name a few.

GR8000 ensures the high rate of return of customers in Automotive Aftermarket, Wide Format Signage, Heat Transfer Apparel, Custom Decals and Stickers, Road& Traffic Reflective Signage and more.

GR8000 Series performs quality cutting in those thin, thick, rigid materials like Paint Protection Film/PPF, Window Tint, High Intensity Prismatic Reflective Sheeting, Magnets, Sandblast Rubber Stencil and common vinyl stickers.

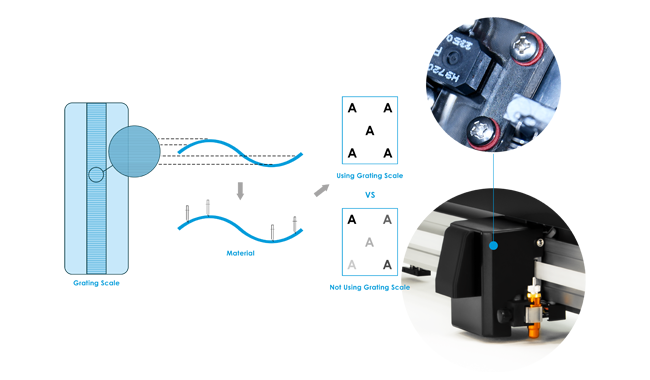

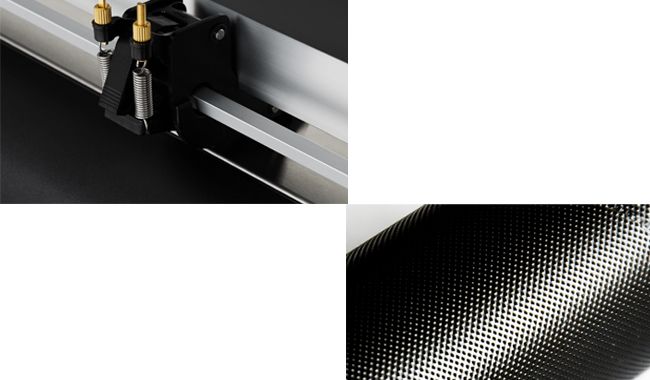

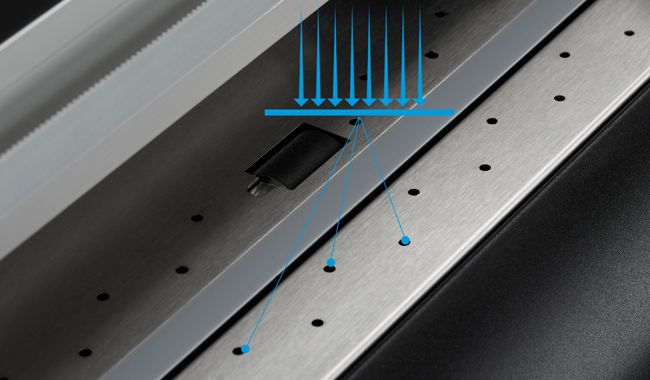

Using Grating Scale

In actual situations, the surface of the machine table and that of the material being processed will inevitably experience certain undulations. This necessitates that the cutting tool be able to float accordingly. Otherwise, issues such as excessive or insufficient cutting depth will arise, which in turn leads to difficulties in smooth waste removal. Outperforming the vast majority of competitors, we took the lead in adopting precise grating scale to detect the distance between the tool-tip and the material surface in real - time. This enables us to adjust the cutting pressure in real - time to regulate the cutting depth. Consequently, a uniform cutting depth within the material can be achieved, allowing for easy waste removal after cutting. Meanwhile, the cutting tool will not damage the surface of the machine table.

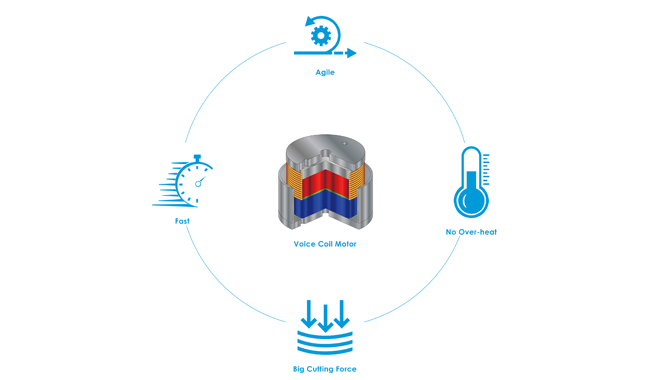

Using Voice Coil Motor

Unlike electromagnets, voice coil motor can execute commands for pressure adjustment with greater sensitivity, thereby ensuring more consistent cutting depths. Moreover, voice coil motor can cut ultra - thin materials with higher precision, as it is capable of outputting a minimum cutting pressure of 20 grams. Additionally, voice coil motor features low noise and do not overheat even after extended periods of operation.

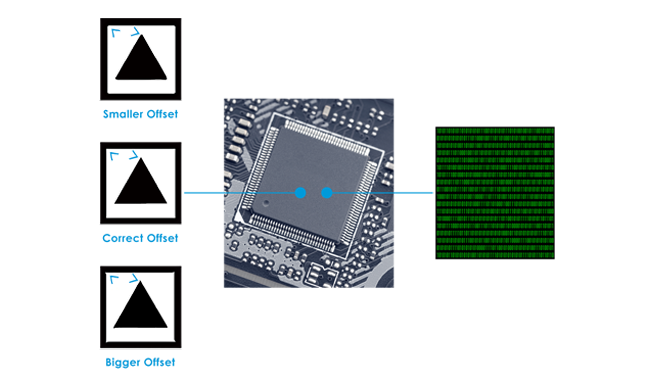

Tool-tip Compensation Has Been Embeded into Chip

Unlike the method of merely using third-party software for tool-tip compensation, we have embedded the tool-tip compensation program into the chip of the control system. This approach effectively avoids the loss of cutting accuracy caused by software changes. As a result, out cutting machine is capable of performing stable high-precision cutting operations.

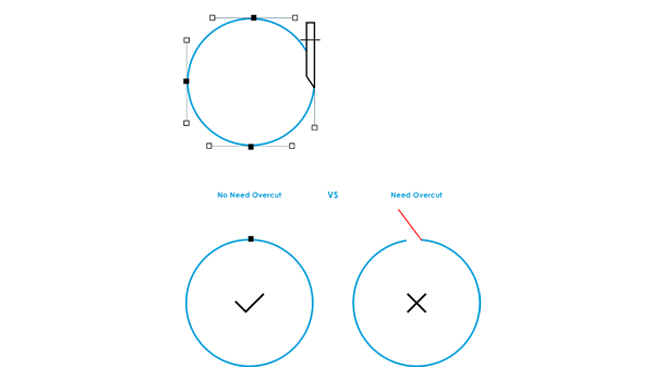

No Need Overcut

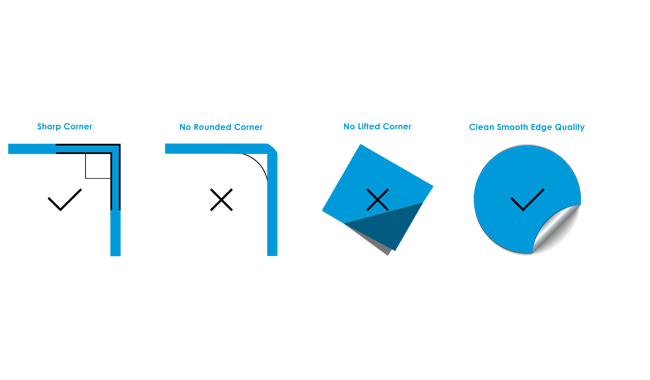

Due to the adoption of advanced motion control algorithms, in each cutting path, the starting and ending points can coincide, eliminating the necessity to set overcutting, more importantly results in a more aesthetically pleasing trimmed interface.

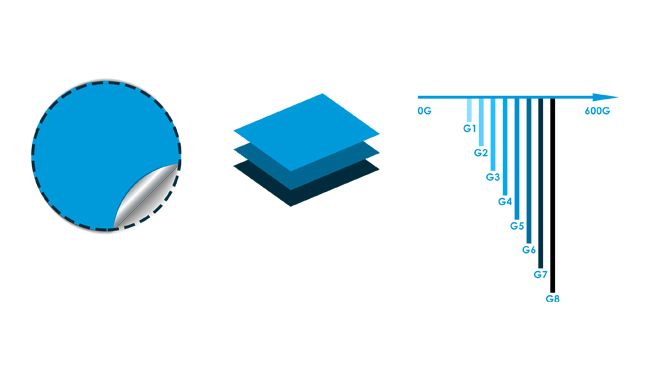

Cutting Pressure is Segmented into 8 Groups

The cutting pressure is dynamically segmented into 8 groups. Based on preconfigured programs, the machine automatically generates distinct tool paths corresponding to different color layers. This is an industry-leading function. Dotted Lines Cutting For single-layer film cutting, we recommend employing the dotted lines cutting mode. This method eliminates workpiece displacement during processing. Upon completion, the substrate can be cleanly detached through manual separation. The dotted ines cutting function requires exceptionally high kinematic stability of the cutting head throughout its vertical travel.

More Convenient to Use, More Efficient to Operate

Based on two decades of industry expertise and frontline users insights, we have continuously upgraded hardware/software performance and operational protocols. This results in proven simplicity and amplified capabilities.

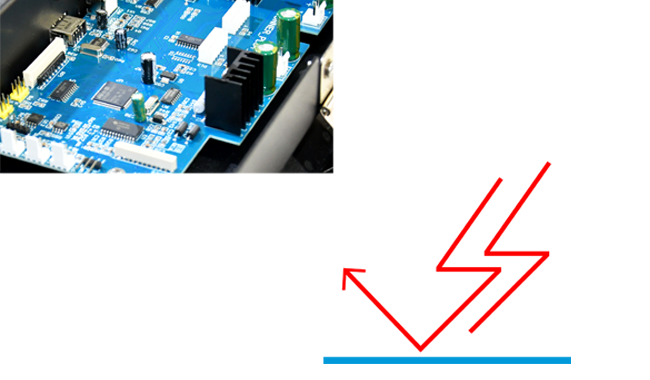

Excellent Anti-static Performance

Static electricity can severely disrupt the operation of a digital cutter. Therefore, we have placed significant emphasis on enhancing the machine's anti - static performance. This measure ensures that the machine can operate smoothly throughout the year, particularly during the autumn and winter seasons when staticelectricity is more prevalent.

Streamlined Operations & User-friendly HMI

Drawing on years of experience accumulated from numerous users, we have continuously optimized the operation steps and methods of our machines. Now, we offer a relatively more concise operation menu, which is conducive to users' efficiency improvement. Tailored to the specific needs of different clients or industries, we are also capable of formulating targeted software and hardware solutions.

Carbon Steel Body, Solid and Robust

We manufacture the frames and chassis from carbon steel, which creates a sturdier and more substantial body. This significantly enhances machine stability during operation, contributing to improved cutting precision.

Accurate Rigid Push Rollers

It is made of three distinct materials (including ABS), maintains shape and accuracy without deformation or precision loss during long-duration processing. Equipped with HIGH and LOW pressure adjustment capabilities, facilitating flexible user settings. High-precision Grit Rollers We utilize premium grit rollers, featuring high friction, precise materials feeding, and exceptional durability.

Stable Accurate Long Length Tracking

Boasting stable and accurate tracking over distances of up to 7 meters (23 feet)—a capability that surpasses most competitors—the GR8000 series delivers reliable long-span performance. This critical feature for high-level processing makes it the ideal solution for large-scale sign and pattern making.

Outstanding Cutting Quality

Our controller adopts advanced motion control algorithms, which effectively improves the cutting accuracy. This is manifested in sharper acute angles that will not be lifted or become rounded.

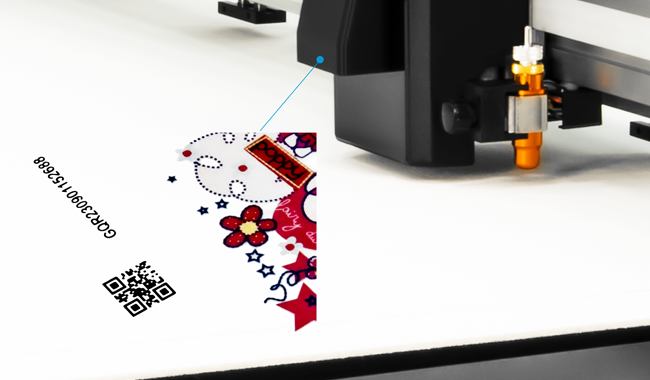

Using QR Code Scanner

With the assistance of a QR code scanner, the cutting machine can independently retrieve and execute the cutting file corresponding to the current work-piece from a multitude of cutting files. This effectively enhances the degree of work automation.

Using CCD Camera

Compared with red laser sensors, CCD cameras can identify the contours of complex shaped images much more rapidly. CCD cameras are capable of recognizing a wider variety of colors and are applicable to a greater number of material types. Our software enables automatic one - click identification of the contours of graphics and the addition of registration marks.

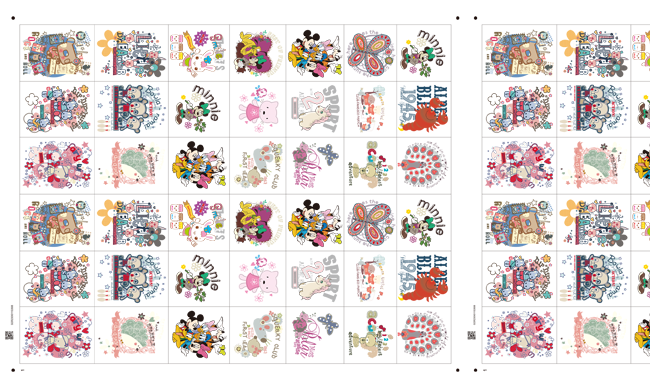

Segmented Area Scanning & Segmented Area Cutting

Our machine has the capabilities of segmented area scanning and segmented area cutting. This feature is crucial for processing long, rolled materials, as it can boost processing efficiency and alleviate the labor burden on workers. Additionally, for exceptionally long graphics, our machine is able to carry out complete cutting without having to split the graphics.

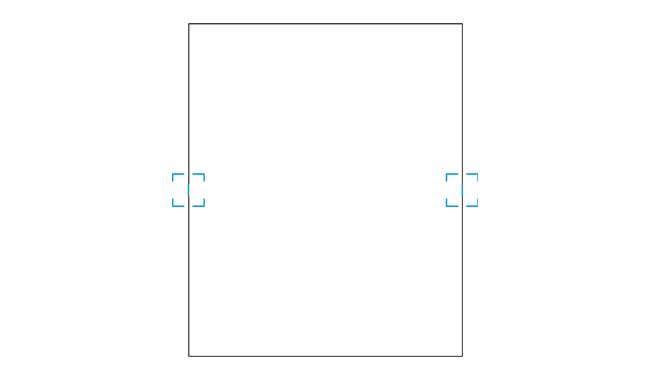

Auto Deviation Calibration Function

Save time on precise material placement. As long as the placement deviation does not exceed ±15 degrees, the cutter can accurately identify the marker points. That's because our control system smartly processes the collected marker point position data to deliver results matching the actual position.

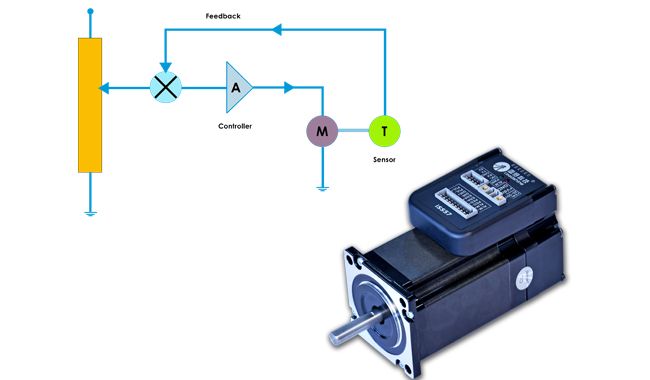

Using Servo Motors

For the X - axis and Y - axis, we have employed servo motors. These servo motors possess encoder feedback capabilities, enabling them to instantaneously and in real - time inform the control system of the position information. As a result, it is conducive to precisely controlling the processing accuracy. The servo motors we utilize meet medical standards, they not only offer outstanding stability but also have features like high - speed operation, high torque output, and quiet running.

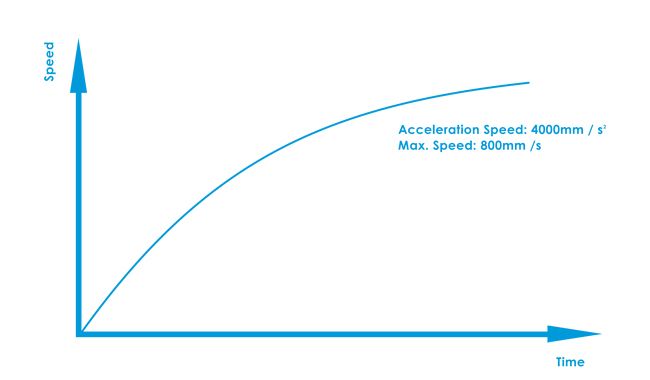

High-speed Cutting/Plotting Operation

With a maximum speed of 800mm/s enabling volume production capabilities, the servo-driven system delivers seamless acceleration profiles, high-torque performance, and outstanding precision. This engineering configuration ensures exceptional operational durability under continuous heavy-duty cycles.

Using Suction Cutting Table

It features high-density vacuum ports and high-volume airflow to securely hold materials flush against the work surface, enabling the Tool Carriage to execute rapid, precision cutting and plotting operations.

Using Material Alignment Marks

Alignment marks are positioned on both front and rear sides of the machine body's right flank. This facilitates convenient determination and adjustment of the material's longitudinal movement direction while enabling visual monitoring of any directional deviation during operation.

Using Material Sensors

Material sensors perform continuous dimensional verification during material loading. If the detected material size is insufficient to accommodate the intended content layout, the system automatically suspends cutting/plotting operations. The controller subsequently prompts the operator to either replenish material stock or scale down the content dimensions.

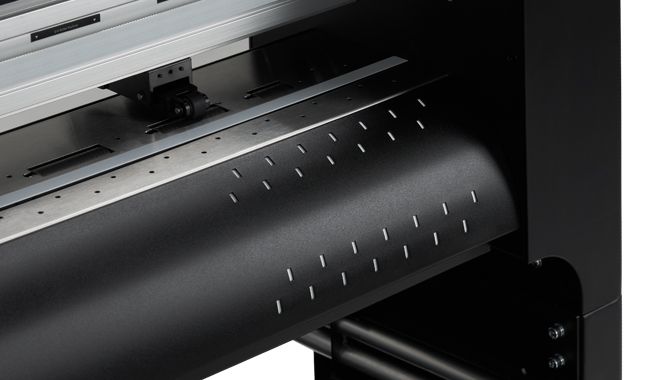

Refined Material Carrier

This component features high load-bearing capacity, smooth rolling action of material rollers. The material rollers maintain end-to-end parallelism during operation.

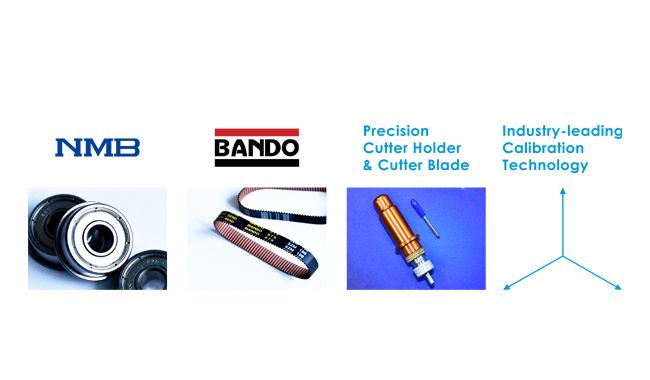

Quality Components & Industry-leading Calibration Technology

Every investment pays off. We carefully choose components from top international brands to build a reliable core for the machine. This ensures long - term, stable, and efficient operation, supporting your production. Also, our product layout considers your needs, so you can buy accessories nearby and maintain the equipment easily. This saves your time and money, letting you focus on business development without worries. During the manufacturing process, we employ industry-leading calibration technology to ensure perpendicularity and parallelism among relevant axes.

Compatible with Popular Professional Software

Our digital cutters have been well - adapted to internationally popular professional software. The main ones include FlexiSIGN & PRINT (produced by SAi), SIGNMASTER, SIGNCUT, CorelDRAW (produced by Corel Corporation) and Digital Factory (produced by FIERY LLC/CADLINK). Additionally, we offer a Software Development Kit (SDK) to enable our customers to adapt other CAD/CAM software.

Compatible with USB Flash Drive and USB Cord for Data Transfer

To facilitate the transfer of cutting files, we have adopted two data reception methods. One is to use a USB flash drive, and the other is to directly connect the cutting machine to a computer via a USB data cable. Users can choose the method they prefer.

Multiple Models Available

We present an extensive selection of machine models in a wide array of sizes. Moreover, we are capable of tailoring these models to meet the specific requirements of our clients, ensuring that every unique need is precisely addressed.

CE Available

Our product is honored to have been awarded the EU CE certification, fully complying with the stringent MD, EMC, and RoHS standards.

Parameters

| Model | GR8000-80 Cutting Plotter | GR8000-140 Cutting Plotter | GR8000-180 Cutting Plotter |

| Max.Cutting Width | 690mm (Non-contour Cutting) | 1290mm (Non-contour Cutting) | 1630mm (Non-contour Cutting) |

| 600mm (Contour Cutting) | 1220mm (Contour Cutting) | 1520mm (Contour Cutting) | |

| Max.Mountable Media Width | 840mm | 1440mm | 1780mm |

| Min.Mountable Media Width | 70mm | ||

| Applicable Media Thickness | ≤1.5mm | ||

| Max.Cutting Speed | 800mm/s | ||

| Max.Cutting Force | 600G / 5.8N in 8 Steps | ||

| Cutting Force Setup | Adjustable in Every 1G | ||

| Drive | Servo | ||

| Mechanical Resolution | 0.0125mm | ||

| Min.Character Size | 3 x 3mm | ||

| IOS | Win10 / 8 / 7 / XP | ||

| Memory Buffer | 2MB | ||

| Software | Windows Driver, SignWorkPro, CADtoPlotpro | ||

| LCD | English / Chinese | ||

| File Format | HP-GL, PLT | ||

| Port in Standard | USB, RS-232 | ||

| CCD Camera | Included | ||

| QR Code Scanner | For option | ||

| Power Input | AC90- 240V,50-60Hz | ||

| Power Consumption | 60w | ||

| Cutter Holder/Pen Holder | 1 for each | ||

| Cutter Blade Diameters | 2.0mm | ||

| Cutter Blade Angles | 30°, 45°, 60° | ||

| Types of Pen | Water based fiber-tip pen & Oil based ball pen | ||

| Method to Fix Material | Push rollers | ||

| Media Stock Roller Plates | Included | ||

| Basket | For option | ||

| Package Size L-W-H | 1180x400x570mm | 1710x400x570mm | 2200x400x570mm |

| Gross / Net Weight | 42/27kg | 96/62kg | 105/72kg |

A cutting plotter is a computer-controlled machine used to cut vinyl sheets. If you're not familiar, vinyl stands for polyvinyl chloride, a self-adhesive plastic that is the third most widely produced plastic polymer.

Vinyl comes in two forms - rigid and flexible. Cutting Plotter are used to cut flexible varieties and have a wide range of uses among hobbyists and small businesses. These include making signs, decals, banners, advertising, fabric designs and home décor. Rigid vinyl is commonly used in the fabrication of pipes and windows and doors.

Most Cutting Plotter look similar to printers and are roughly the same size. Some come with stands that you can use to cut different heights.

Cutting Plotter are controlled by computer software, of which there are many to choose from, depending on the compatibility of your machine. Use the software to design and then send commands to the cutter to cut the desired shape.

The cutter moves left and right and rotates according to the software instructions as the vinyl moves underneath it. The material is then "weeded" to remove the excess vinyl.

Today, many of the best cutting plotter are also capable of cutting a range of other materials, including soft and hard materials.

Brochure

DownLoad Brochure