GR8090F, a special purpose auto-feeding flatbed cutting plotter for DTF industry with features optimized according to characters of material applied in the DTF field.

QR code scanner is available since 2024.

Super easy installation, one-key operation and high efficiency make GR8090F a right-hand man for DTF, Heat transfer apparel industries.

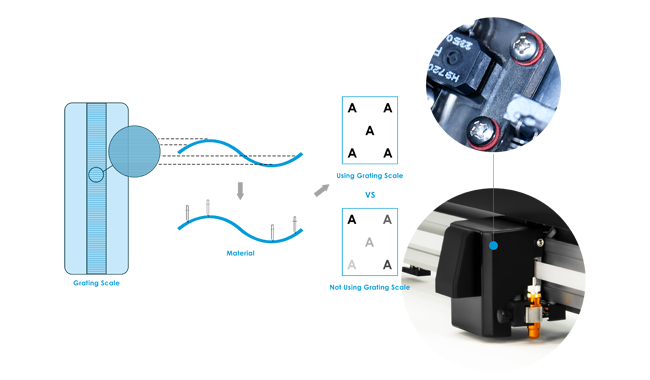

Grating Scale

In actual situations, the surface of the machine table and that of the material being processed will inevitably experience certain undulations. This necessitates that the cutting tool be able to float accordingly. Otherwise, issues such as excessive or insufficient cutting depth will arise, which in turn leads to difficulties in smooth waste removal. Outperforming the vast majority of competitors, we took the lead in adopting precise grating scale to detect the distance between the tool-tip and the material surface in real - time. This enables us to adjust the cutting pressure in real - time to regulate the cutting depth. Consequently, a uniform cutting depth within the material can be achieved, allowing for easy waste removal after cutting. Meanwhile, the cutting tool will not damage the surface of the machine table.

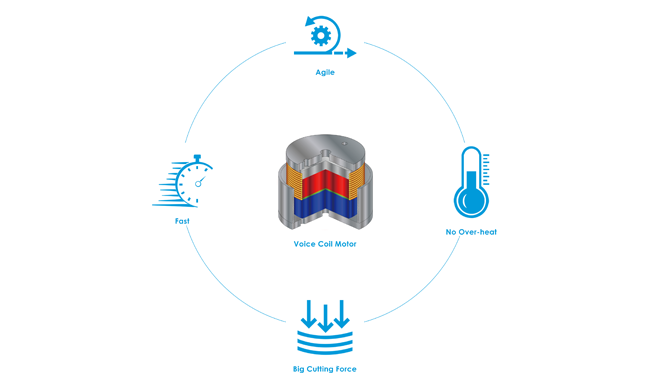

Using Voice-coil Motor

Unlike electromagnets, voice coil motor can execute commands for pressure adjustment with greater sensitivity, thereby ensuring more consistent cutting depths. Moreover, voice coil motor can cut ultra - thin materials with higher precision, as it is capable of outputting a minimum cutting pressure of 20 grams. Additionally, voice coil motor features low noise and do not overheat even after extended periods of operation.

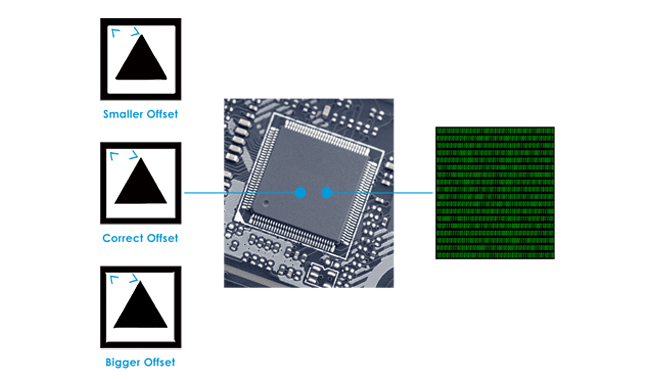

Tool-tip Compensation Has Been Embeded into Chip

Unlike the method of merely using third-party software for tool-tip compensation, we have embedded the tool-tip compensation program into the chip of the control system. This approach effectively avoids the loss of cutting accuracy caused by software changes. As a result, out cutting machine is capable of performing stable high-precision cutting operations.

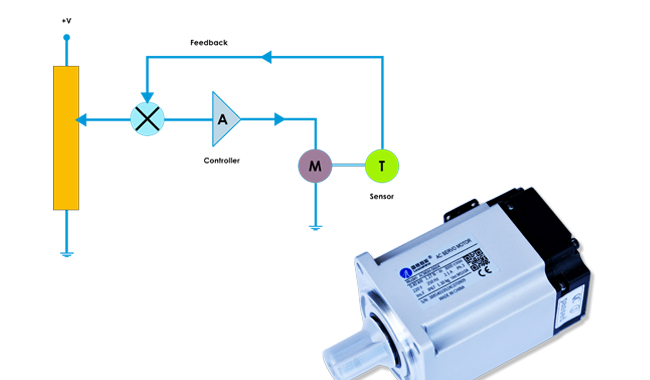

Using Servo Motors

For the X - axis and Y - axis, we have employed servo motors. These servo motors possess encoder feedback capabilities, enabling them to instantaneously and in real - time inform the control system of the position information. As a result, it is conducive to precisely controlling the processing accuracy. The servo motors we utilize meet medical standards, they not only offer outstanding stability but also have features like high - speed operation, high torque output, and quiet running.

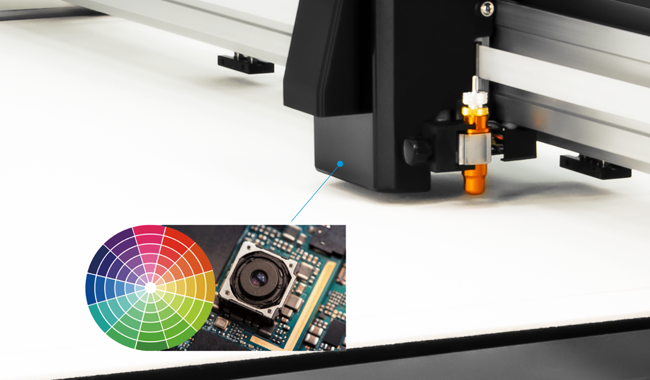

Using CCD Camera

Compared with red laser sensors, CCD cameras can identify the contours of complex shaped images much more rapidly. CCD cameras are capable of recognizing a wider variety of colors and are applicable to a greater number of material types. Our software enables automatic one - click identification of the contours of graphics and the addition of registration marks.

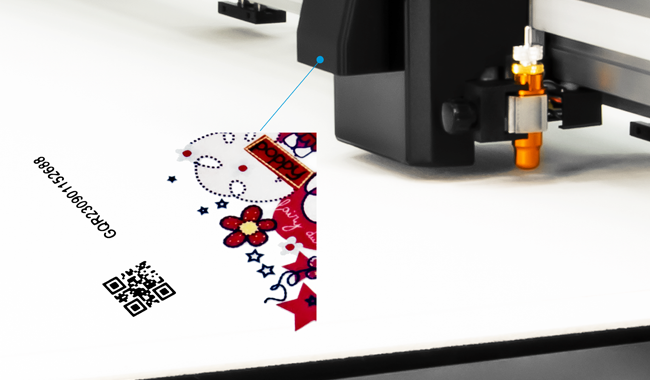

Using QR Code Scanner

With the assistance of a QR code scanner, the cutting machine can independently retrieve and execute the cutting file corresponding to the current work-piece from a multitude of cutting files. This effectively enhances the degree of work automation.

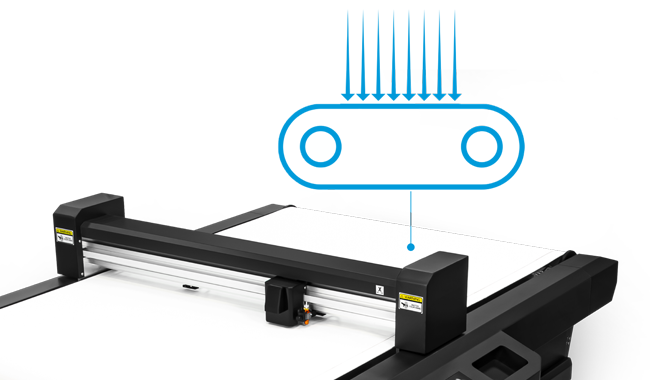

Using Vacuum Table

The vacuum worktable boasts excellent levelness,which contributes to the precise control of the cutting depth. Equipped with a dense array of air - suction ports, the worktable can firmly and evenly fix the materials being processed. As a result, both the cutting speed and precision are significantly enhanced.

Using Auto-feeding System

The automatic feeding system enables seamless connection for extra - long format cutting/ plotting processing. In cooperation with the CCD camera, it can achieve fast and precisely guided nested cutting and contour cutting.

Parameters

| Model | GR8090F |

| Working Size on X Axis | 820mm (Non-contour Cutting) |

| 800mm (Contour Cutting) | |

| Working Size on Y Axis | Sheet Material: 910mm |

| Roll Material: Whole Roll | |

| Max.Media Width Applicable | 830mm |

| Applicable Media Thickness | ≤1.0mm |

| Applicable Media | PET, PVC |

| Method to Feed Media | Conveyor & Roll Media Bracket |

| Method to Fix Media | Vacuum Table |

| Max. Cutting Speed | 600mm / s |

| Max. Cutting Force | 600G / 5.8N in 8 Steps |

| Cutting Force Setup | Adjustable in Every 1G |

| Cutter Blade Diameters | Φ2.0mm |

| Cutter Blade Angles | 30°, 45°, 60° |

| Dotted Lines Cutting | Included |

| Drive | AC Servo |

| Mechanical Resolution | 0.0125mm |

| IOS | Win11 / 10/ 8 / 7 |

| Memory Buffer | 2MB |

| CAD/CAM Software | Windows Driver, neostampa, Flexi, Cadlink ( Digital Factory v11) |

| LCD | English / Chinese |

| File Format | HP-GL, PLT |

| Port in Standard | USB, RS-232 |

| Registration Marks Recognition | CCD Camera |

| Power Input | AC 90-240v, 50-60Hz |

| Power Consumption | 2.2kw |

| Cutter Holder | 1 |

| QR Code Scanner | Included |

| Roll Media Bracket | Included |

| Floor Plan W-L-H | 1240 x 1800 x 1030mm |

| Package Size W-L-H | 1400 x 1600 x 1250mm |

| Gross / Net Weight | 330 / 280kg |

Brochure

DownLoad Brochure